Provide your architectural vision with elite curtain wall systems. As a specialist manufacturer, we engineer high-performance, design-forward curtain walls. From planning through delivery, our qualified team supplies complete support aimed at the highest standards of quality and performance.

- Browse our portfolio of advanced curtain wall systems engineered for project-specific demands.

- We leverage modern techniques and superior materials to manufacture robust, long-lifespan curtain walls.

- We integrate sustainable practices into our production cycle to support greener outcomes.

Allow us to serve as your reliable collaborator in bringing architectural plans to life. Contact us today to discuss your project and discover the benefits of working with a top-tier curtain wall manufacturer.

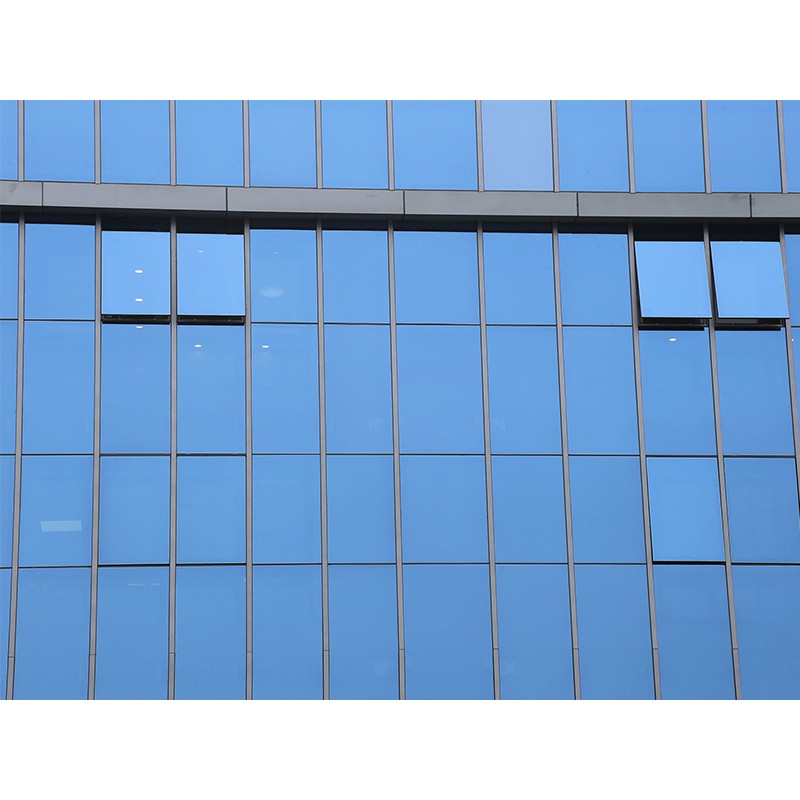

High-clarity glass systems enhancing both appearance and building performance: Raising Design Standards and Operational Efficiency

Contemporary glass curtain walls bring together compelling aesthetics and considered engineering for better buildings These glazed façades foster visual continuity and an expansive feel that complements the site. Manufactured using joined glass panes, they enhance interior brightness with plentiful daylight.

Beyond appearance, glass curtain walls are engineered for outstanding efficiency and lifespan. They present advanced insulating capabilities that minimize energy demand and emissions. Plus, these systems endure environmental stress while preserving build quality and reliability. Specifying glass variants, pane sizes, and frame systems enables bespoke curtain wall solutions that balance form and function.

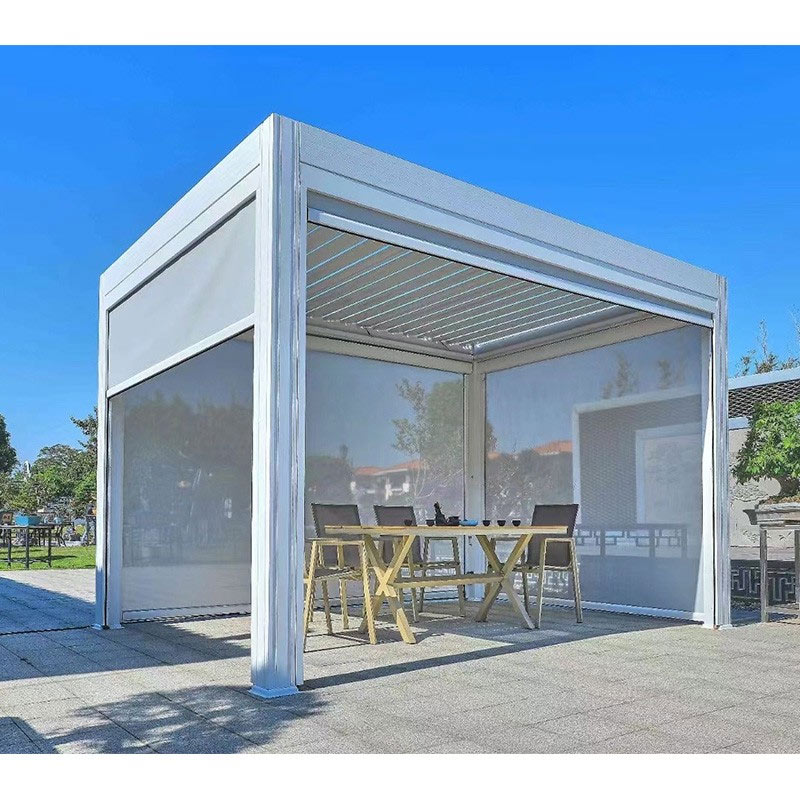

Aluminum curtain walls deliver strength, longevity, and broad design freedom: Mechanical Strength, Sustained Durability, and Versatile Styling

Curtain walls bring contemporary aesthetic clarity together with measurable operational results. Among building materials, aluminum curtain walls stand out for their high structural strength, remarkable long-term durability, and wide-ranging design flexibility.

Designed for climatic resilience, aluminium curtain walls resist rust, color degradation, and physical wear.

Aluminum’s malleability enables architects to realize intricate shapes, curved façades, and bespoke designs that push creativity.

Furthermore, properly specified curtain walls lower energy demand and operating costs through improved insulation.

Range of coatings including matte, satin, powder-coated and anodized finishes helps harmonize façades with design intent.

Chinese curtain wall producers lead in technical advances and manufacturing quality

China’s curtain wall industry is undergoing strong growth propelled by demand for modern architectural solutions.

These manufacturers are recognized for their strict dedication to product quality and industry standards.

Continuous innovation efforts lead to the evolution of new curtain wall technologies and products.

This R&D focus leads to the creation of advanced materials, system designs, and fabrication technologies.

The innovation pipeline produces curtain walls that satisfy design aspirations and functional demands alike.

A defining trait of many Chinese manufacturers is adaptability and the ability to customize solutions for unique projects.

These firms collaborate with design teams and owners to convert ideas into practical façade solutions.

Tailor-Made Curtain Wall Solutions Crafted for Your Architectural Goals Adjusted to Meet Your Project Brief

Let us implement your architectural aspirations using personalized curtain wall solutions. We recognize each project is unique and commit to producing custom designs that perfectly complement your aesthetic. Whether your style is modern and minimal or timeless and classic, our designers work with you to create curtain walls that combine usefulness with beauty.

- With advanced engineering and manufacturing methods, your curtain wall will be robust and energy-conscious.

- A wide palette of materials, finishes and glazing configurations lets you meet both performance and visual goals.

- Gain access to premium manufacturing, careful finishing and strong customer support during the whole process.

glass curtain wall

State-of-the-art glass curtain walls serving modern architectural needs

The latest architectural trends favor advanced materials and systems that deliver both beauty and utility.

High-performance glass curtain walls are a preferred option for transparency and thermal effectiveness.

They utilize insulated glass panes with gas mixtures to improve thermal resistance and efficiency.

Support structures are engineered to provide stable performance through extreme weather events.

These curtain walls improve the aesthetic experience through generous glazing and visual cohesion.

- Standout architectural façades with refined visual impact

- Improved energy efficiency via advanced glazing technologies

- Superior thermal control delivering enhanced comfort and reduced running costs

- Durability and robustness to resist harsh environmental impacts

- Boosted natural illumination for more pleasant and productive interiors

Aluminum as a medium for innovative curtain wall design

Aluminum has emerged as an increasingly popular choice for curtain wall frames due to its blend of strength and lightness Aluminum’s resilience and minimal weight enable elegant façade designs that endure.

Cutting-edge curtain walls generally feature aluminium components along with glazed elements and other materials.

They accommodate a range of styles from minimalist aesthetics to intricate patterned façades.

Eco-conscious curtain wall design and advanced engineering

In modern projects, curtain walls provide both an architectural statement and structural competency That said, traditional manufacturing approaches can carry environmental costs. Eco-aware curtain wall design targets lower environmental cost via recycled inputs and improved construction practices.

Material choices strongly influence the environmental credentials of curtain wall systems. Eco-friendly alternatives such as recycled glass, reclaimed timber, and responsibly sourced bamboo can lower the construction footprint.

Energy-optimizing features are typically integrated into eco-conscious curtain wall designs.

- Eco-focused engineering values longevity and reduced repair cycles to extend building lifespan.

- Through green engineering, buildings become both comfortable for occupants and gentler on the environment.

Coherent fusion of aluminium systems with existing façade elements

Designers now expect façade systems to be inventive while meeting functional needs Aluminium façades are favored due to their combination of architectural advantages and technical benefits.

- They can be customized with different glazing strategies to optimize daylight and sightlines.

Overall, aluminium curtain walls provide an effective union of style and performance for building exteriors.

Investigating the design possibilities and functions of glass curtain walls

Glass curtain walls have become widespread in contemporary architecture, combining visual elegance with pragmatic use Offering wide vistas and increased daylight, glass façades make interiors feel airy and open.

- Constructed primarily with aluminium or steel frames, these walls are recognized for their structural strength and durability

- Contemporary glass technology has produced glazing options with improved thermal control, sound attenuation, and security features

Chinese curtain wall firms are instrumental in advancing façade engineering on the world stage

In recent times, China’s curtain wall sector has expanded rapidly and become internationally influential.

This growth is supported by public investments in infrastructure and increasing demand for sustainable façades.

Their production approaches aim to satisfy international criteria and client expectations.

Partnerships with research institutes underpin ongoing material and system innovation across the industry.